X-RINGS FROM THE MANUFACTURER

Solutions for static and dynamic applications

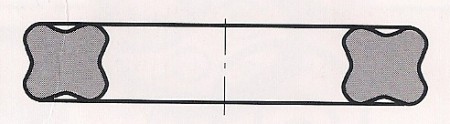

The X-rings have the same essential features as O-rings. It is suitable for axial / radial static and also radial dynamic applications. Lubricant can collect between the sealing lips, which is an advantage for dynamic applications. Depending on the material used, a wide temperature range is covered, as with O-rings. As a rule, X-rings are inserted into the same groove dimensions as standard O-rings. It can be used as an internal or external seal and against changing pressure directions. The X-ring achieves its sealing effect by compressing its cross-section. As an X-ring manufacturer, CIMAKA responds to the individual requirements of its customers.

Advantages of the X-ring, possibly the solution to your problem, include

- the X-ring requires smaller deformation forces to achieve a comparable sealing effect.

- the four sealing lips of the X-rings result in a higher sealing performance, as the compression is more favorably distributed and at the same time form a lubricating groove, which has a wear-inhibiting effect.

- A major advantage of the X-ring is its inherent stability. In dynamic applications (piston seals, rod seals), where an O-ring rolls in the groove and is therefore subject to torsion, an X-ring will only shift.

- the X-ring is easy to install and requires little installation space.

Grundsätzlich sind X-Ringe mit einem Innendurchmesser (ID) < 700 mm aus einem Werkzeug (keine Werkzeugkosten).

As an X-ring manufacturer, we offer many material variants. For example, we supply parts made from NBR, HNBR, EPDM, silicone, FPM / FKM etc.

Questions or inquiries, please contact us.