PTFE SHAFT SEALS

CIMAKA DLS PTFE shaft seals, the universal shaft seal, space-saving and efficient, up to 30 bar pressure, +300°C temperature, very good dry-running properties and shaft diameters up to 300 mm, from 300 mm on request.

The DLS lip seals fit into the smallest installation spaces. Due to the material properties, we cover a wide range of applications. The shaft seal is axially clamped or bolted.

Advantages

- Smallest installation dimensions

- Simple assembly

- interchangeable

Materials

PRGR, black

PTFE standard, self-lubricating black, resistant to chemicals and solvents, temperature-resistant, abrasion-resistant

PRPI, yellow

For mechanical, thermal and chemical applications, Excellent wear resistance, Resistant to continuous temperatures, High creep resistance Not suitable in combination with alkalis (bases)

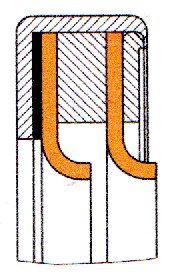

The DLS shaft seals can be arranged in a wide range of variants to suit the application, e.g. double seals for abrasive media, double-sided with barrier or cooling chamber, etc.

Installation dimensions of the DLS shaft seals

| Shaft diam. | Wave gap | min. Clamping place |

| 3 to 30 mm | 2.5 mm | 2.5 mm |

| 30 to 69 mm | 2.5 mm | 3.0 mm |

| 70 to 250 mm | 3.0 mm | 5.0 mm |

| 250 to ... | 4.0 mm | 10.0 mm |

Versions in prefabricated housings are also available. The housings, a turned version, are manufactured according to customer specifications (installation space, application). The entire housing is then pressed into the intended installation space. There is no risk of incorrect arrangement due to improper installation. The materials for the housings are 1.4301, 1.4401 or 1.4571, special materials such as Hastelloy or titanium can also be manufactured. Send us your inquiry, we will be happy to advise you.

Standard versions with deep-drawn housings

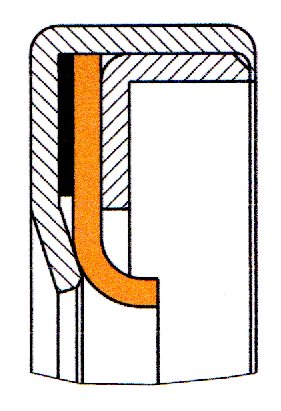

Type DLS-M01C

- up to 30 m/s

- up to 10 bar

- for dry running and insufficient lubrication

Type DLS-MDC

- High tightness with media

- against abrasive media